STAINLESS Stol Bearbechtung Pipe Tube

Beschreiwung

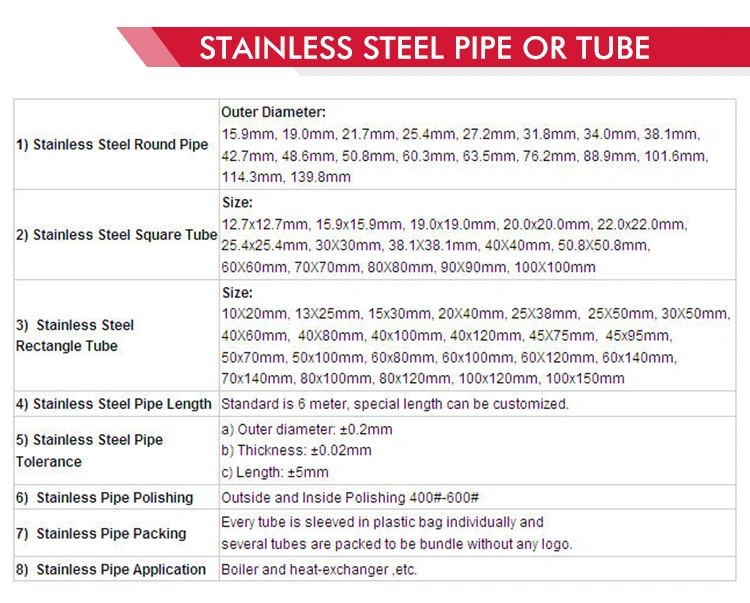

| Numm | Edelstol Nahtlos & geschweißte Tube & Pipe. | ||||||

| Standard | ASTM A554, A249, A269 an A270

| ||||||

| Material Grad | 201: Ni 0,8%~1% | ||||||

| 202: Ni 3,5%~4,5% | |||||||

| 304: Ni 8%, Cr 18% | |||||||

| 316: Ni 10%, Cr 18% | |||||||

| 316L: Ni 10%~14% | |||||||

| 430: Cr16%6~18% | |||||||

| baussenzegen Duerchmiesser

| 10-1000 mm | ||||||

| Dicke | 1-100 mm | ||||||

| Längt | 6m oder als Client Ufro | ||||||

| Toleranz | a) Baussenduerchmiesser: +/- 0,2 mm | ||||||

| b) Dicke: +/- 0,02 mm | |||||||

| c) Längt: +/- 5 mm | |||||||

| Uewerfläch | 180G, 240G, 320G Satin / Hairline 400G, 600G Spiegelfinish | ||||||

| Applikatioun | Gelänner, Gelänner, Trap, Schweißmeshbildschierm, Dier, Fënster, Balkon, Zait, Bänk, Miwwelen, etc | ||||||

| Test | Squash Test, verlängert Test, Waasserdrocktest, Kristallrottest, Hëtzt Behandlung, NDT | ||||||

| chemesch Zesummesetzung vum Material

| Material Zesummesetzung | 201 | 202 | 304 | 316 | 316l | 430 |

| C | <=0.15 | <=0.15 | <=0.08 | <=0.08 | <=0.035 | <=0.12 | |

| Si | <=1.00 | <=1.00 | <=1.00 | <=1.00 | <=1.00 | <=1.00 | |

| Mn | 5,5-7,5 | 7,5-10 | <=2.00 | <=2.00 | <=2.00 | <=1.00 | |

| P | <=0.06 | <=0.06 | <=0.045 | <=0.045 | <=0.045 | <=0.040 | |

| S | <=0.030 | <=0.030 | <=0.030 | <=0.030 | <=0.030 | <=0.030 | |

| Cr | 13-15 | 14-17 | 18-20 | 16-18 | 16-18 | 16-18 | |

| Ni | 0,7-1,1 | 3,5-4,5 | 8-10,5 | 10.0-14.00 Uhr | 10.0-14.00 Uhr | ** | |

| Mo | ** | ** | ** | ** | 2,0-3,0 | ** | |

| Ronn Rouer Gréisst | 12,7x1,0, 15,8x1,2, 19,1x1,2, 25,4x1,2 | ||||||

| véiereckege Rouer | 25,4x25,4x1,2 ,25,4x25,4x2,0 , 31,8x31,8x1,2 ,38,1x38,1x1,5 | ||||||

| Rechteck Tube | 40x20x1,5, 50x25x1,5 | ||||||