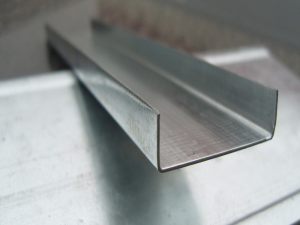

321 STAINLESS Stol Sträif

STAINLESS Steel Sheet Plate Grad Baogu Fourniture

| Typ | Grad | Grad | Chemeschen Komponent % | ||||||||||

| C | Cr | Ni | Mn | P | S | Mo | Si | Cu | N | Aner | |||

| Austenitesch | 201 | SUS 201 | ≤0,15 | 16.00-18.00 Uhr | 3.50-5.50 | 5,50-7,50 | ≤0,060 | ≤0,030 | - | ≤1.00 | - | ≤0,25 | - |

| 202 | SUS 202 | ≤0,15 | 17.00-19.00 Uhr | 4.00-6.00 | 7.50-10.00 | ≤0,060 | ≤0,030 | ≤1.00 | - | ≤0,25 | - | ||

| 301 | 1.431 | ≤0,15 | 16.00-18.00 Uhr | 6.00-8.00 | ≤2.00 | ≤0,045 | ≤0,030 | - | ≤1.00 | - | ≤0,10 | - | |

| 304 | 1.4301 | ≤0,07 | 17.00-19.00 Uhr | 8.00-10.00 | ≤2.00 | ≤0,045 | ≤0,030 | - | ≤1.00 | - | - | - | |

| 304l | 1.4307 | ≤0,030 | 18.00-20.00 Uhr | 8.00-10.00 | ≤2.00 | ≤0,045 | ≤0,030 | - | ≤1.00 | - | - | - | |

| 304H | 1.4948 | 0,04-0,10 | 18.00-20.00 Uhr | 8.00-10.00 | ≤2.00 | ≤0,045 | ≤0,030 | - | ≤1.00 | - | - | - | |

| 309 | 1.4828 | ≤0,20 | 22.00-24.00 Uhr | 12.00-15.00 Uhr | ≤2.00 | ≤0,045 | ≤0,030 | - | ≤1.00 | - | - | - | |

| 309S | * | ≤0,08 | 22.00-24.00 Uhr | 12.00-15.00 Uhr | ≤2.00 | ≤0,045 | ≤0,030 | - | ≤1.00 | - | - | - | |

| 310 | 1.4842 | ≤0,25 | 24.00-26.00 Uhr | 19.00-22.00 Uhr | ≤2.00 | ≤0,045 | ≤0,030 | - | ≤1,50 | - | - | - | |

| 310S | * | ≤0,08 | 24.00-26.00 Uhr | 19.00-22.00 Uhr | ≤2.00 | ≤0,045 | ≤0,030 | - | ≤1,50 | - | - | - | |

| 314 | 1.4841 | ≤0,25 | 23.00-26.00 Uhr | 19.00-22.00 Uhr | ≤2.00 | ≤0,045 | ≤0,030 | - | 1.50-3.00 | - | - | - | |

| 316 | 1.4401 | ≤0,08 | 16.00-18.50 Uhr | 10.00-14.00 | ≤2.00 | ≤0,045 | ≤0,030 | 2.00-3.00 | ≤1.00 | - | - | - | |

| 316l | 1.4404 | ≤0,030 | 16.00-18.00 Uhr | 10.00-14.00 | ≤2.00 | ≤0,045 | ≤0,030 | 2.00-3.00 | ≤1.00 | - | - | - | |

| 316 Ti | 1.4571 | ≤0,08 | 16.00-18.00 Uhr | 10.00-14.00 | ≤2.00 | ≤0,045 | ≤0,030 | 2.00-3.00 | ≤1.00 | - | 0.1 | Ti5(C+N)~0,70 | |

| 317 | * | ≤0,08 | 18.00-20.00 Uhr | 11.00-15.00 Uhr | ≤2.00 | ≤0,045 | ≤0,030 | 3.00-4.00 | ≤1.00 | - | 0.1 | - | |

| 317l | 1.4438 | ≤0,03 | 18.00-20.00 Uhr | 11.00-15.00 Uhr | ≤2.00 | ≤0,045 | ≤0,030 | 3.00-4.00 | ≤1.00 | - | 0.1 | - | |

| 321 | 1.4541 | ≤0,08 | 17.00-19.00 Uhr | 9.00-12.00 | ≤2.00 | ≤0,045 | ≤0,030 | - | ≤1.00 | - | - | Ti5(C+N)~0,70 | |

| 321 H | * | 0,04-0,10 | 17.00-19.00 Uhr | 9.00-12.00 | ≤2.00 | ≤0,045 | ≤0,030 | - | ≤1.00 | - | - | Ti5(C+N)~0,70 | |

| 347 | 1.455 | ≤0,08 | 17.00-19.00 Uhr | 9.00-12.00 | ≤2.00 | ≤0,045 | ≤0,030 | - | ≤1.00 | - | - | Nb≥10*C%-1,10 | |

| 347 H | 1.494 | 0,04-0,10 | 17.00-19.00 Uhr | 9.00-12.00 | ≤2.00 | ≤0,045 | ≤0,030 | - | ≤1.00 | - | - | Nb≥10*C%-1,10 | |

| xm-19 | Nitronic 50 | ≤0,06 | 20.50-23.50 Uhr | 11.50-13.50 Uhr | 4,0-6,0 | ≤0,045 | ≤0,030 | 1.50-3.00 | ≤1.00 | - | 0,2-0,4 | Nb: 0,10-0,30 V: 0,10-0,30 | |

| 9 04l | N08904 | ≤0,02 | 19.0-23.00 Uhr | 23.0-28.0 | 4,0-5,0 | ≤0,045 | ≤0,035 | ≤1.00 | 0.1 | Cu: 1,0-2,0 | |||

| Duplex | 2205 | S32205 | ≤0,03 | 22.0-23.0 | 4,5-6,5 | ≤2.00 | ≤0,030 | ≤0,020 | 3,0-3,5 | ≤1.00 | - | 0.14-0.20 | |

| 2507 | S32750 | ≤0,03 | 24.0-26.0 | 6,0-8,0 | ≤1,20 | ≤0,035 | ≤0,020 | 3,0-5,0 | ≤0,80 | 0,5 | 0,24-0,32 | ||

| * | S32760 | ≤0,03 | 24.0-26.0 | 6,0-8,0 | ≤1.00 | ≤0,030 | ≤0,010 | 3.0-4.0 | ≤1.00 | 0,5-1,00 | 0,2-0,3 | ||

| 2304 | S32304 | ≤0,03 | 21.5-24.5 | 3,0-5,5 | ≤2,50 | ≤0,040 | ≤0,030 | 0,05-0,6 | ≤1.00 | 0,05-0,6 | 0,05-0,2 | ||

| 329 | 1.446 | ≤0,08 | 23.00-28.00 Uhr | 2.00-5.00 | ≤1.00 | ≤0,040 | ≤0,030 | 1.00-2.00 | ≤0,75 | - | - | ||

| Ferrit | 409 | S40900 | ≤0,03 | 10.50-11.70 | 0,5 | ≤1.00 | ≤0,040 | ≤0,020 | - | ≤1.00 | - | ≤0,030 | Ti6(C+N)~0.50 Nb:0.17 |

| 430 | 1 kr17 | ≤0,12 | 16.00-18.00 Uhr | - | ≤1.0 | ≤0,040 | ≤0,030 | - | ≤1.0 | - | - | - | |

| 444 | S44400 | ≤0,025 | 17.50-19.50 Uhr | 1 | ≤1.00 | ≤0,040 | ≤0,030 | 1,75-2,5 | ≤1.00 | - | 0,035 | Ti+Nb: 0,2+4(C+N)~0,80 | |

| 446 | S44600 | ≤0,20 | 23.00-27.00 Uhr | 0,75 | ≤1,5 | ≤0,040 | ≤0,030 | 1.50-2.50 | ≤1.00 | - | ≤0,25 | - | |

| Martensite | 410 | 1 kr13 | 0,08-0,15 | 11.50-13.50 Uhr | 0,75 | ≤1.00 | ≤0,040 | ≤0,030 | - | ≤1.00 | - | - | - |

| 410S | * | ≤0,080 | 11.50-13.50 Uhr | 0.6 | ≤1.00 | ≤0,040 | ≤0,030 | - | ≤1.00 | - | - | - | |

| 416 | Y1Cr13 | ≤0,15 | 12.00-14.00 Uhr | 3) | ≤1,25 | ≤0,060 | ≥0,15 | - | ≤1.00 | - | - | - | |

| 420 | 2 kr13 | ≥0,15 | 12.00-14.00 Uhr | - | ≤1.00 | ≤0,040 | ≤0,030 | - | ≤1.00 | - | - | - | |

| 420 j2 | 3 kr13 | 0,26-0,35 | 12.00-14.00 Uhr | - | ≤1.00 | ≤0,040 | ≤0,030 | - | ≤1.00 | - | - | - | |

| 431 | 1Cr17Ni2 | ≤0,20 | 15.00-17.00 Uhr | 1.50-2.50 | ≤1.00 | ≤0,040 | ≤0,030 | - | ≤0,80 | - | - | - | |

| 440 C | 11 Kr17 | 0,95-1,20 | 16.00-18.00 Uhr | - | ≤1.00 | ≤0,040 | ≤0,030 | 0,75 | ≤1.00 | - | - | - | |

| PH | 630 | 17-4PH | ≤0,07 | 15.00-17.50 Uhr | 3.00-5.00 | ≤1.00 | ≤0,035 | ≤0,030 | - | ≤1.00 | 3.00-5.00 | - | Nb 0,15-0,45 |

| 631 | 17-7 Uhr u | ≤0,09 | 16.00-18.00 Uhr | 6.50-7.50 | ≤1.00 | ≤0,035 | ≤0,030 | - | ≤1.00 | ≤0,50 | - | Al 0,75-1,50 | |

| 632 | 15-5PH | ≤0,09 | 14.00-16.00 Uhr | 3.50-5.50 | ≤1.00 | ≤0,040 | ≤0,030 | 2.00-3.00 | ≤1.00 | 2,5-4,5 | - | Al 0,75-1,50 | |

Beschreiwung

321 STAINLESS Stol Sträif ass eng Zort austenitesche STAINLESS Stol mat niddereg Kuelestoff Inhalt a gutt corrosion Resistenz zu vill korrosive Ëmfeld.321 bitt exzellent Schweessbarkeet, gutt Veraarbechtbarkeet an aussergewéinlech Fabrikatiounseigenschaften.

321 STAINLESS Stol Sträif gëtt allgemeng an der chemescher Industrie benotzt, Pulp a Pabeier Industrie, Marine an Offshore Ingenieur Industrien wéi och an der Liewensmëttel a Gedrénks Industrien.

321 STAINLESS Stol Sträif huet och eng héich Resistenz zu Chlorid Stress corrosion Rëss a Pitting.Et ass och resistent géint Salzsäure bei héijen Temperaturen bis 250 ° C (480 ° F).

Eegeschaften

Gutt Korrosiounsbeständegkeet: 321 Edelstahlstreifen huet besser Korrosiounsbeständegkeet wéi 304 an 316 Aarte vun Edelstol, wat et ideal mécht fir a korrosive Ëmfeld ze benotzen.

Excellent Weldability: 321 STAINLESS Stol Sträif kann duerch all Methoden dorënner Arc Schweess (TIG / GTAW), Elektronen Strahl Schweess (EBW / EFW), Ënnerdaach Arc Schweess (SAW) a Laser Strahl Schweess (LBIW) geschweest ginn.

Héich Stäerkt: D'Kraaftniveauen vum 321 Edelstahlstrip si bis zu 50% méi héich wéi déi vun 304 Aarte vun Edelstahl a bis zu 80% méi héich wéi déi vun 316 Aarte vun Edelstahl wéinst hirem erhéicht Kuelestoffgehalt an Austenitkorngréisst.